CABLE HARNESS

Menu

Cable Harness

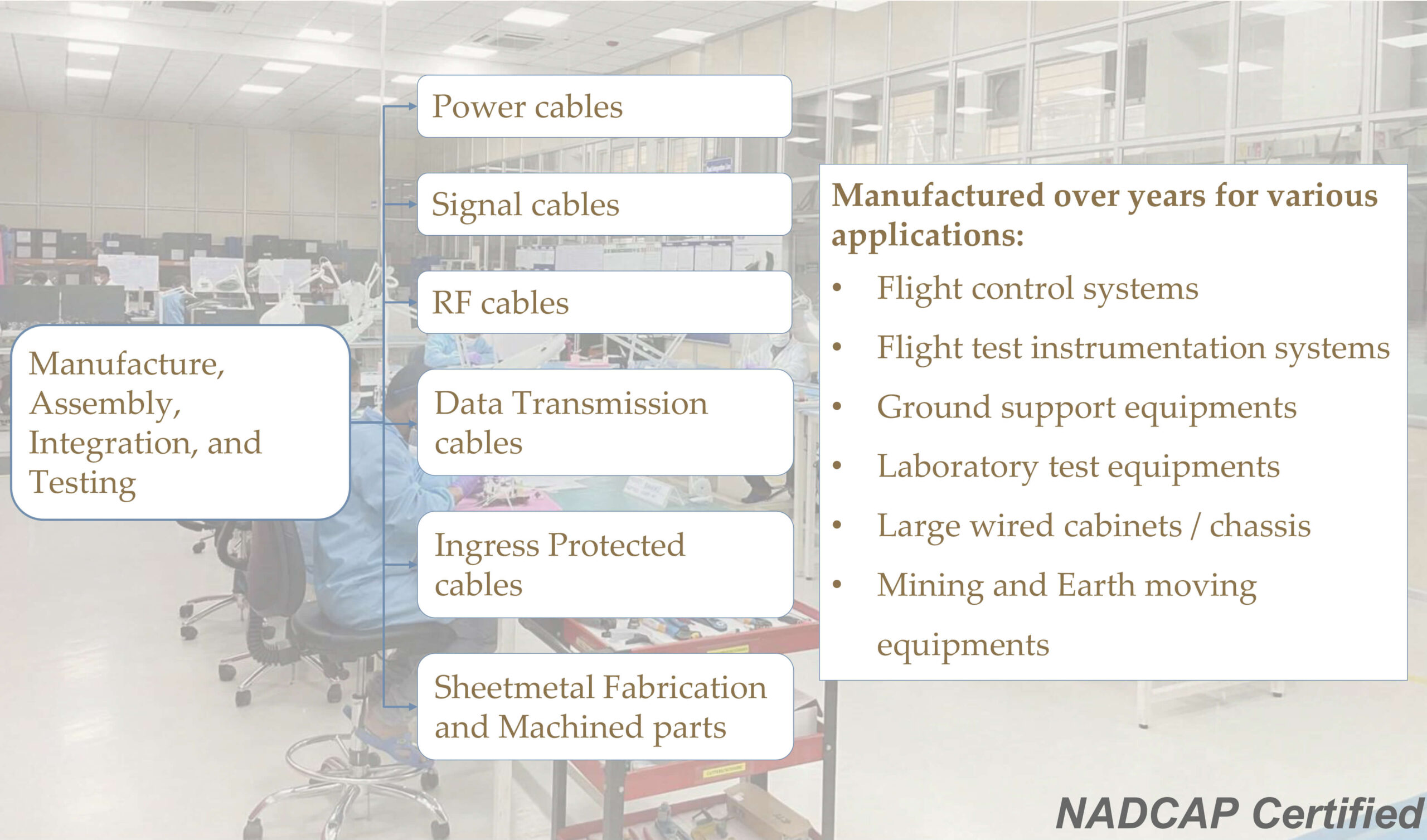

We are manufacturing different types of Cable Harnesses which are used in Aerospace, Marine and Défense applications. Our facility YTPL is NADCAP certified for Cable harness manufacturing.

Cable & Wire Harness Capabilities

- Manufactured up to 10 meters length (can go longer)

- Cables handled – Halogen free, Co-axial, Shielded TP, Braided, PTFE Insulated, Power, Ethernet, USB, Semi-rigid cables, Flat ribbon cables, Multi core cables, DVI cables, Audio cables.

- Connectors – ARINC connector, D-Type & Sub-D connector, Ethernet connector, Power connector, Fisher connector, IDC connector, CMA connector, Circular connector (Ex-D3899, MIL DTL), straight plug connector and SMT/PTH/Press-Fit types

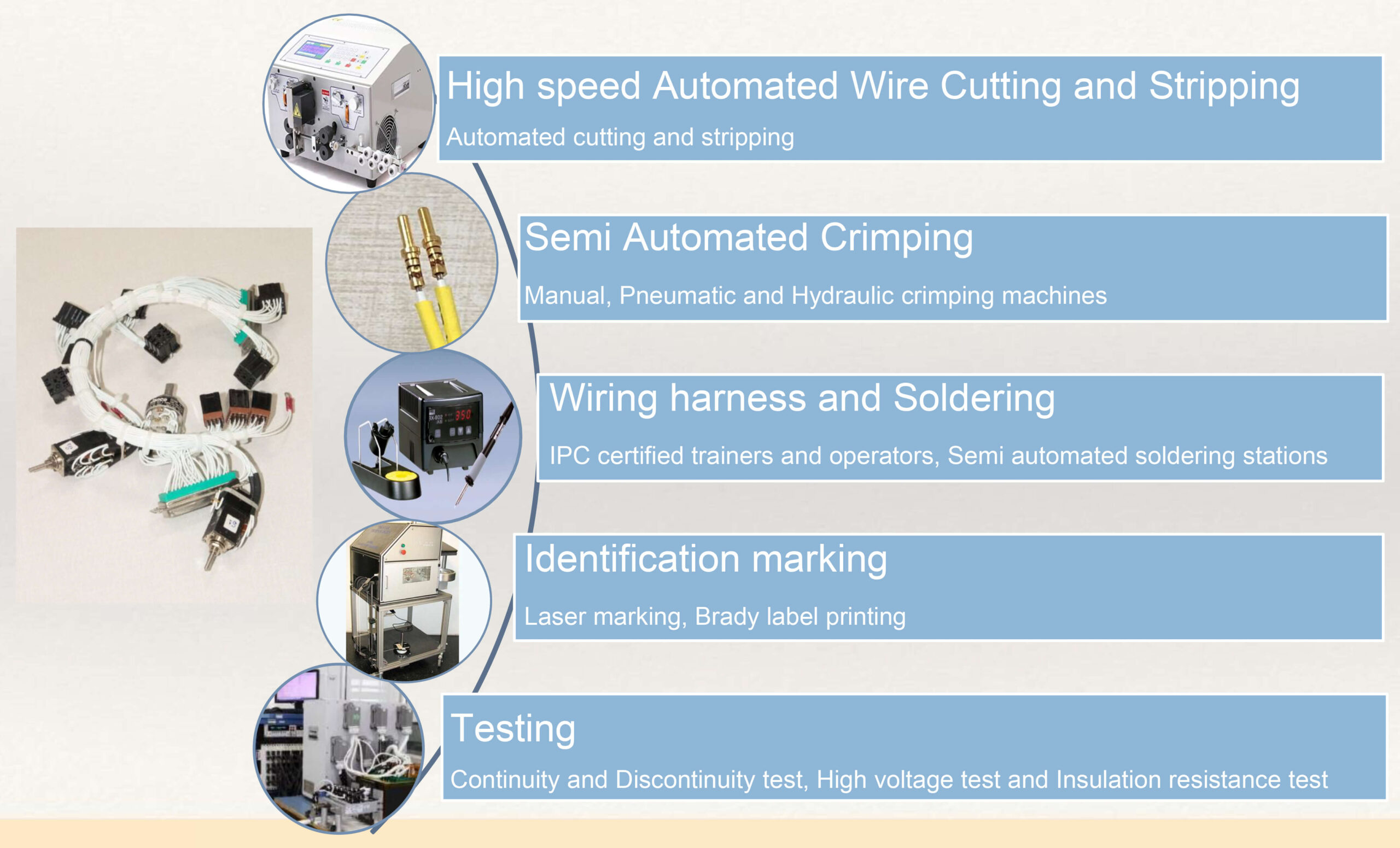

- Processes – Crimping, Heat shrinking, Solderless wire wrapping, Epoxy Moulding, Lapp Joint soldering, Splicing, Braided Shield Termination, Laser Marking on wires, Label Marking, Banding/Tinel Ring, Y Type/Right Angle/ Straight type Heat shrink Boot Sleeving, single core and multi core cable harness, Complex & Multi branch cable harness using form boards.

- Experience in Twinax, Triax & Quadrax cables and connectors (BNC, TNC, SMA..)

Manufacturing Process

End Applications

- Wired racks/cabinets/panel types for submarines, Navy consoles, Night Vision Camera

- Ethernet cables, Military aircraft RADAR

- Custom Power Cables, Test Cables for Flight Test Equipment, Lab testing cable

Testing

- Validation tests (Pull test, Push-Out Test, Retention test)

- Electrical test (Harness Tester- up to 1000 channels – Continuity/ Discontinuity/ DWV/ IR/ SWR/ Insertion Loss)

Certifications

- IPC-J-STD-001 & IPC-610 Certified In-house Trainers & Operators

- IPC/WHMA-A-620 Certified In-house Trainer & Operators

- NADCAP Certified (Hical Subsidiary unit YTPL)