PRECISION MACHINING

Menu

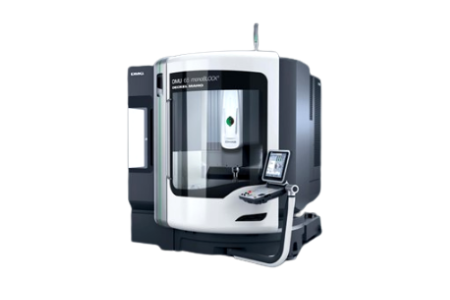

Precision Machining

Our Machining centre supplies complex Aeronautics, Space and Military products with critical tolerances and applicable Aerospace special process.

Hical in-house capabilities

- Sheet Metal Bending

- Precision Machining

- Turret Punching

- Aluminium spot welding as per AWS D17.2 – NADCAP Certified

- Aluminium Fusion welding as per AWS D17.1 – NADCAP Certified

- Fastener Fixing – Spin, Impact and Pop Up

- Heli coil fixing as per PN17.70-1

- Descaling process

- In-house tool/fixture/gauges design and manufacturing

- Design of Special Purpose Machines

- Buffing Process

Materials experience/knowledge

- Aluminium: All series of Aluminium (6061, 6063, 2014, 7075, 5052)

- Stainless Steel: All series of SS (AISI 410, AISI 430F, AISI 420, AISI 304, AISI 316, AISI 321, AISI 347, AISI 416, 17-4PH, 15-5PH)

- Carbon Steel: C1018, C1215, Magnetic Iron Bars.

- Special alloys: Nickel alloy, Hiperco 50, Titanium, Custom 465.

- Brass (260, 360) and Copper Alloy (ETP)

Metrology

- Coordinate Measuring Machine (CMM)

- Digital height Master (Up to 700 mm)

- Universal Tester- Tensile/Compression x 2 Nos (Max 190 and 1000 Kgs)

- Metallographic Testing (Zoom from 11X to 67X)

- Video Measurement System x 2 Nos

- Roughness Tester

- Hardness Tester

- Air gauge for very high precision measurement

- Customized inspection gauges

- Contour Tester (Awaiting Installation)

Hical - Machining Section